This project is a 20MWp agricultural light complementary photovoltaic power generation project in Jiande. It is planned to be built in Nanpu Village, Shouchang Town, Jiande City, Zhejiang Province, with a total construction land of 400,000㎡. The design service life is 25 years, and the average annual power generation on-grid is 20019.3MW h. The construction of this power station was completed in 2015 and was connected to the grid for power generation in 2016. After grid-connected power generation, the power generation efficiency is 50%, which is much lower than that of photovoltaic power stations of the same scale. There is no obvious factor that will induce the reduction of power generation in the on-site environment. Therefore, it is necessary to analyze the data of the battery panel to find out the reason.

1.Engineering goals

In this project, a total of 220 photovoltaic panels in 2 strings will be installed with component monitoring modules and data sampling and analysis will be performed. Find out why power generation is inefficient

2.On-site environment

The vegetation on the site is dense, and the vegetation will be higher than the height of the modules to form occlusions, and the surrounding mountains will also form occlusions at certain times of the day. At the same time, the color of the modules in the string is inconsistent, and the preliminary estimate is the color difference caused by the inconsistent attenuation of the modules.

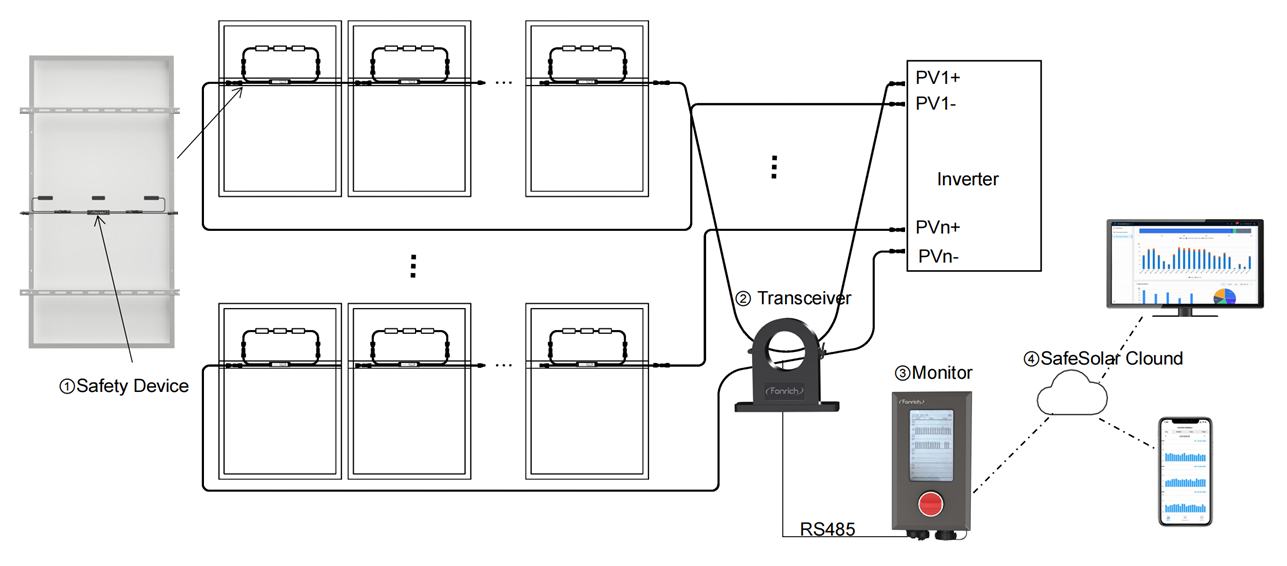

3.System Diagram

4.Site construction

(1) Module monitoring end module installation

(2) Collection box installation

5.Analysis processing

After the module data is uploaded to the cloud platform through the collection box, Fonrich PV Management System will analyze the status of the modules, find out the problem modules and report them in time. Through module data comparison, it can be analyzed that:

(1) Whether the module is in the occlusion state, calculate the influence of plant occlusion and mountain occlusion on power generation.

(2) Whether the attenuation rate of the modules is consistent. Calculate the impact of inconsistent module attenuation on power generation.

(3) Module grounding status, module-to-ground voltage

(4) Real-time status monitoring of modules.

6.Equipment composition

System solutions

| Name | Quantity | Function | Function |

| ①Safety Controller | 22*5*2=220 | Voltage, Current, Temperature Monitoring, Component Level Fast Shutdown | PLC communication loop <1KM |

| ②Smart Transceiver | 2 | Read tail module monitoring data through PLC | |

| ③Collection box | 1 | Used to collect data and access the Internet | |

| ④Cloud server | Analyze, manage plant data | ||

| ⑤Fonrich PV Management System | Display and manage power station data |