In the operation and maintenance of PV power plants, low power generation efficiency and large power loss have always been a headache for operation and maintenance personnel. Low power generation efficiency may be caused by various factors, such as component abnormality, component occlusion, module accumulation, and MPPT failure. Conventional operation and maintenance cannot effectively solve such problems. Located in the 20MWp agricultural and photovoltaic complementary PV power station of State Power Investment Corporation in Jiande City, Zhejiang Province, the reason for the low photovoltaic power generation has been preliminarily analyzed by using Fonrich's module IoT and safety protection scheme for 2 months. The following is a detailed data demonstration.

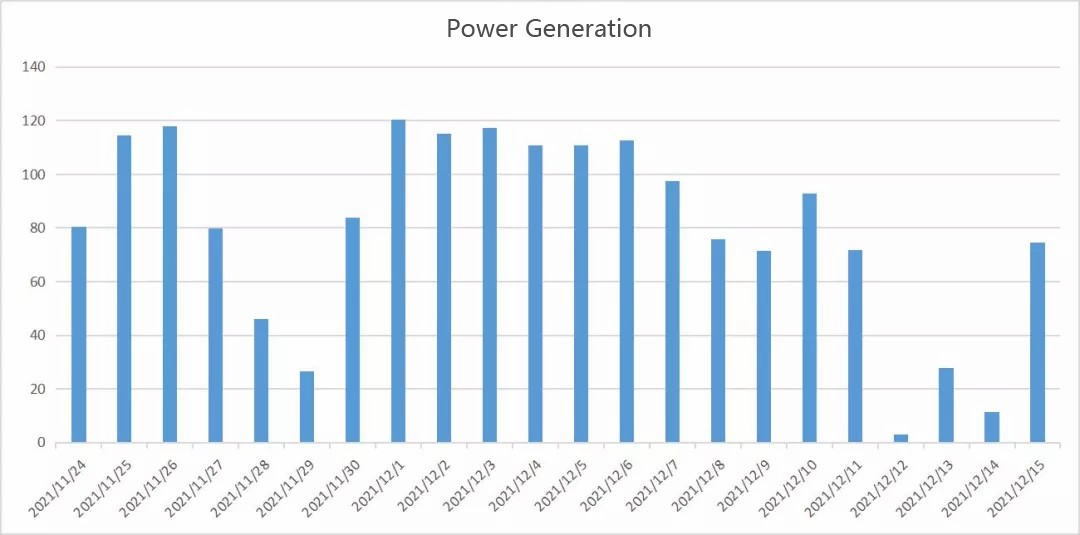

1.Power generation analysis

Total power generation: 1762.27kWh

Total lost power generation: 174.54kWh

Percentage of total power lost: 9.9%

| Date | Power Generation (kWh) | Total Loss (kWh) | Loss Percentage |

| 2021/11/24 | 80.5162 | 5.6159 | 6.97 |

| 2021/11/25 | 114.3602 | 9.7766 | 8.55 |

| 2021/11/26 | 117.7779 | 9.7854 | 8.31 |

| 2021/11/27 | 79.7865 | 7.7391 | 9.70 |

| 2021/11/28 | 46.0023 | 3.3145 | 7.21 |

| 2021/11/29 | 26.5772 | 2.7861 | 10.48 |

| 2021/11/30 | 83.9544 | 8.2659 | 9.85 |

| 2021/12/1 | 120.5157 | 14.3987 | 11.95 |

| 2021/12/2 | 115.2152 | 13.5085 | 11.72 |

| 2021/12/3 | 117.3081 | 13.9122 | 11.86 |

| 2021/12/4 | 110.7681 | 12.0415 | 10.87 |

| 2021/12/5 | 110.6371 | 12.8249 | 11.59 |

| 2021/12/6 | 112.7549 | 11.3614 | 10.08 |

| 2021/12/7 | 97.4537 | 8.0278 | 8.24 |

| 2021/12/8 | 75.9412 | 7.635 | 10.05 |

| 2021/12/9 | 71.5402 | 6.6965 | 9.36 |

| 2021/12/10 | 92.9073 | 8.5614 | 9.21 |

| 2021/12/11 | 71.634 | 4.6404 | 6.48 |

| 2021/12/12 | 2.9986 | 1.4 | 46.69 |

| 2021/12/13 | 27.785 | 3.4648 | 12.47 |

| 2021/12/14 | 11.2647 | 3.1612 | 28.06 |

| 2021/12/15 | 74.571 | 5.6185 | 7.53 |

| Total | 1762.2695 | 174.5363 | 9.9 |

The average daily power generation loss is about 10%, which is significantly higher than the loss ratio of ordinary photovoltaic power stations

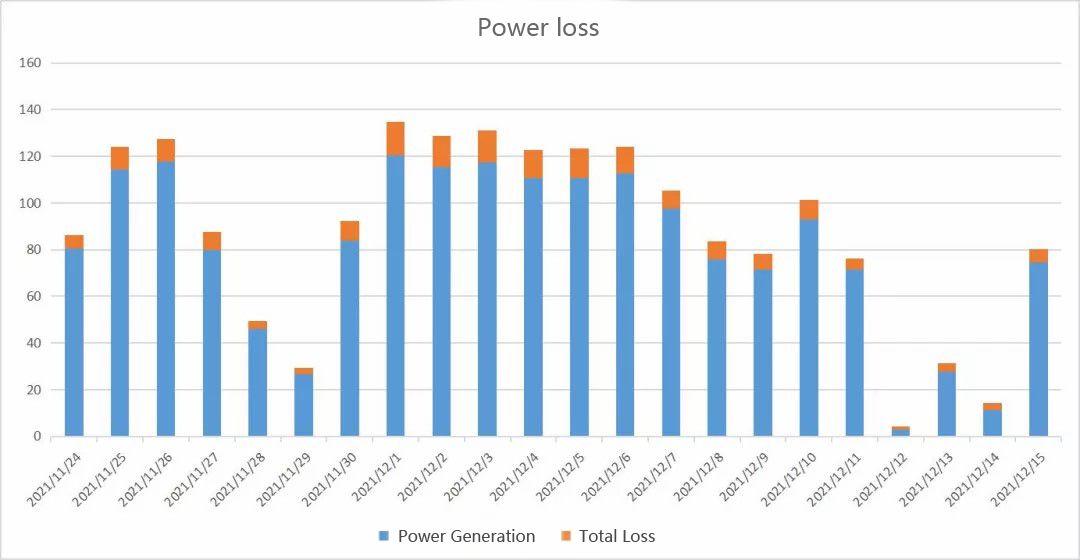

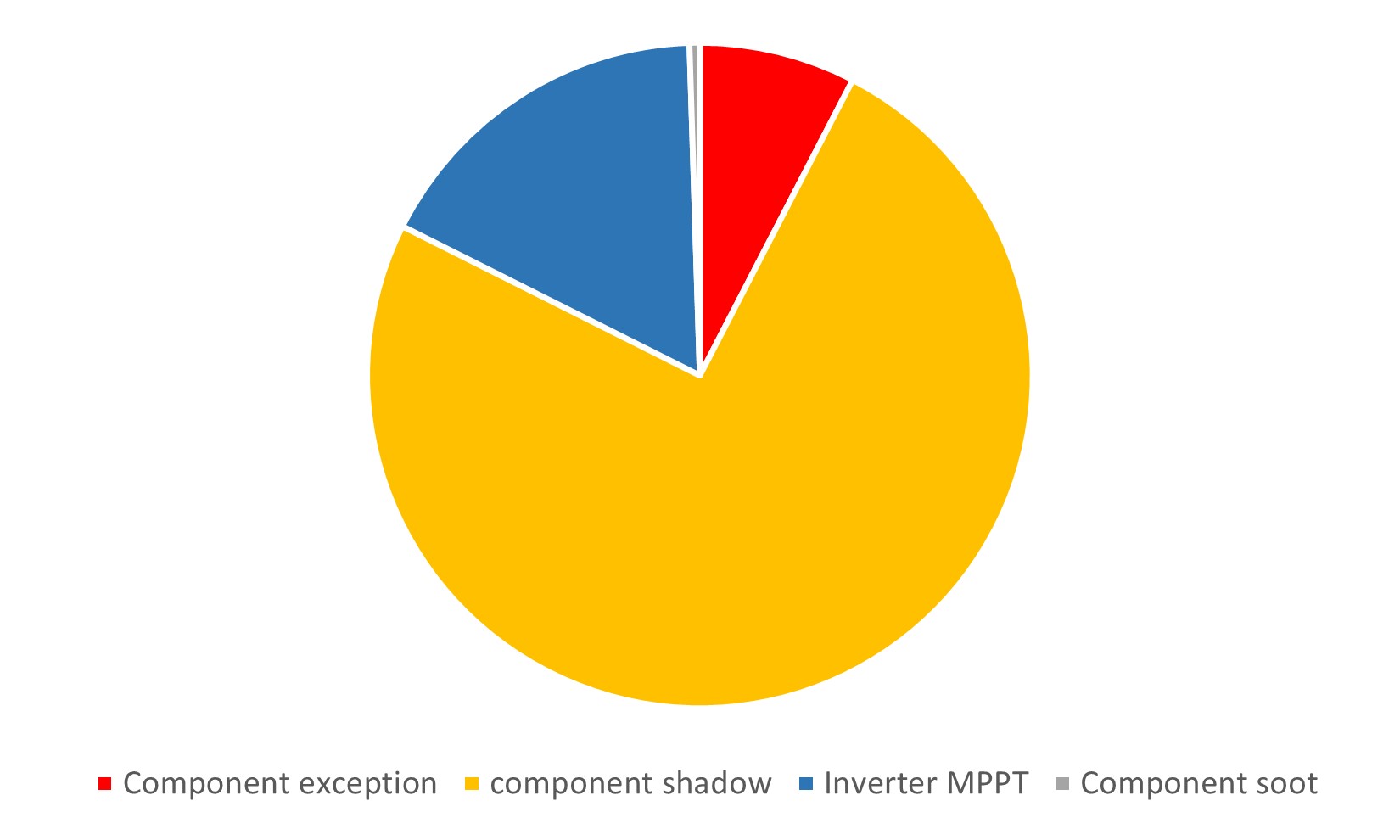

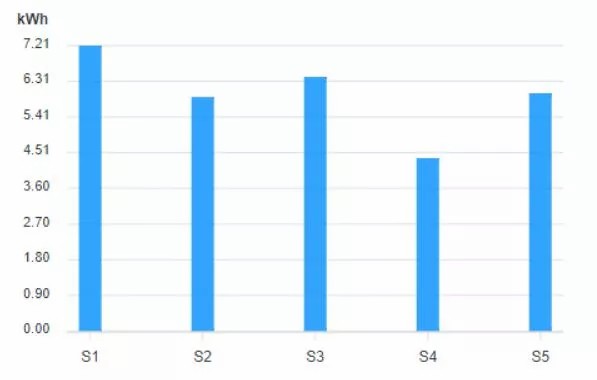

2.Loss Type Analysis

| Loss Type | Lost Electricity Generation (kWh) | Lost Percentage |

| Component exception | 13.22 | 0.75 |

| Component Shadow | 130.52 | 7.41 |

| Inverter MPPT | 29.92 | 1.70 |

| Component dust accumulation | 0.88 | 0.04 |

| Total | 174.54 | 9.90 |

Through data analysis, it is found that the power station has a small proportion of losses due to dust accumulation, but a large proportion of component shadows and inverter MPPT failures. It can be concluded that the operation and maintenance personnel of this power station are very attentive and clean the power station in a timely manner, but the problems of component shadowing and inverter MPPT failure cannot be solved through routine operation and maintenance.

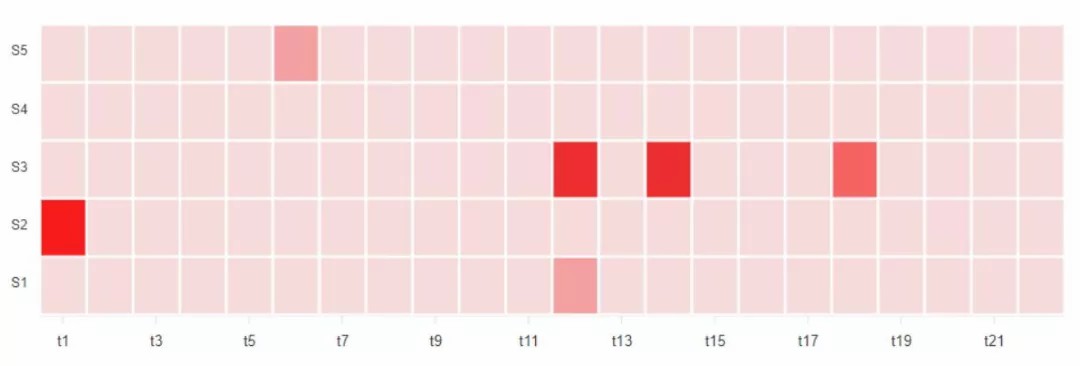

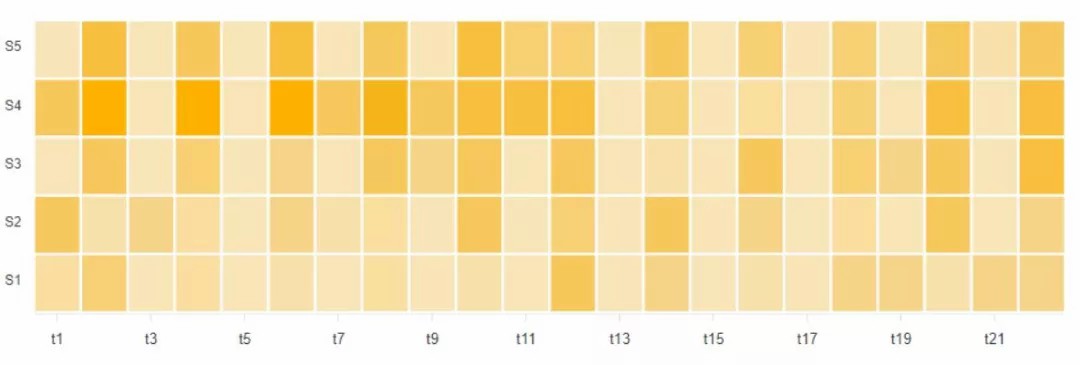

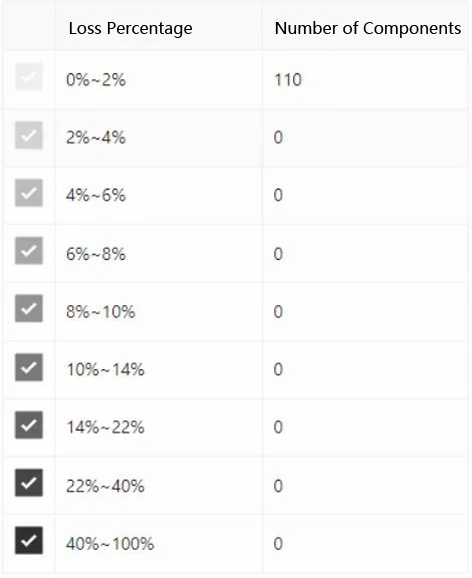

3.Module abnormal loss analysis

Abnormal moudule will cause series loss in the string. If the inverter MPPT is input by multiple channels in parallel, it will lead to mismatch loss between strings and parallels. The following figure shows the thermal diagram of abnormal loss of modules. The darker the color of the module, the more serious the abnormal loss. If the abnormal loss ratio of the module exceeds 10%, it is recommended to replace the module to improve the overall power generation.

Module abnormal loss heat map

4.Module shadow loss analysis

Shaded components will cause series loss in the string. If the inverter MPPT is input by multiple channels in parallel, it will lead to mismatch loss between strings and parallels. The darker the color of the module, the more serious the abnormal loss, and the shadow loss ratio of the module exceeds 10%. It is recommended to solve the shadow problem and improve the overall power generation.

Component shadow loss heatmap

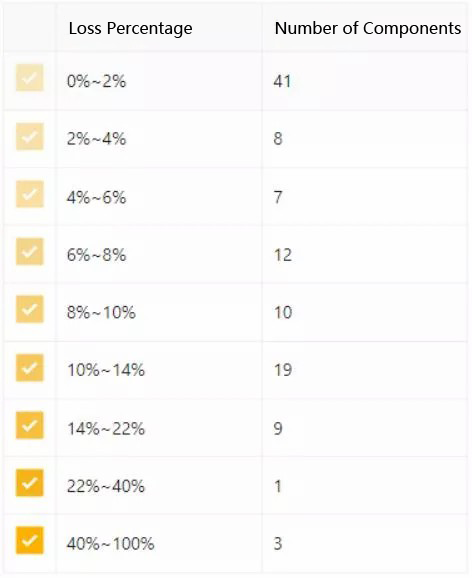

5.Inverter MPPT loss analysis

MPPT loss caused by parallel mismatch between strings; inverter power reduction operation will cause MPPT loss; inverter aging and sampling distortion will cause MPPT loss; inverter MPPT loss will affect the overall power generation of the power station! When the inverter MPPT loss percentage is greater than 4%, it is recommended to replace the inverter.

| String | Lost power generation (kWh) | Loss percentage |

| 1 | 7.21 | 0.41 |

| 2 | 5.91 | 0.34 |

| 3 | 6.42 | 0.36 |

| 4 | 4.37 | 0.25 |

| 5 | 6.01 | 0.34 |

| Total | 29.92 | 1.70 |

Inverter MPPT loss ratio

6.Module soiling loss analysis

The soiling of the module will affect the overall power generation. It is recommended that the module should be cleaned when the soiling loss ratio of the module is greater than 4%.

Module soiling loss heat map

7.The benefits of module IoT and security protection

Module-level data reports, quickly locate faulty modules, increase power generation, and improve operation and maintenance efficiency

Fonrich Safety Photovoltaic-Data Report, which analyzes in detail the power loss of abnormal moudules, shadow modules, soiling modules and inverter MPPT, and locates the position of modules, which greatly improves the efficiency of operation and maintenance. After targeted adjustment After that, the power generation capacity of the power station can be increased.

The low-voltage modules are automatically turned off to protect the modules and increase the power generation of the string

When there is an abnormality or shadow in the module, the voltage of the module drops, and the end module will actively shut down the output of the module, eliminating the impact of the abnormality and shadow on the string, protecting the module and improving the power generation of the string.

A variety of shutdown methods to escort the safety of the power station

Manual shutdown:

During rescue, the main control is manually turned off, and the module voltage drops to 0V within 30S

Through the main control fixed-point shutdown of the problem modules, quickly solve the failure of power generation

Automatic shutdown:

The monitor is powered down

String break

Overtemperature

Arc fault accident

Various fault detection to solve the pain points of power station operation and maintenance

Arc Detection:

Parallel arc

Series arc

Arc fault location

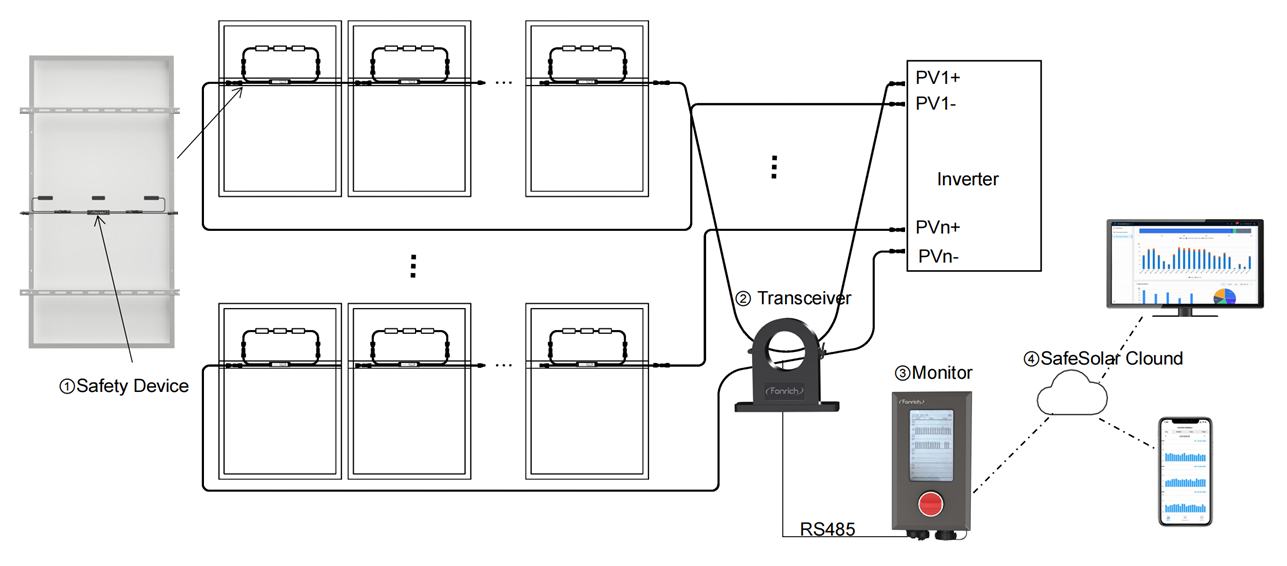

8.System diagram

System solutions

| Name | Quantity | Function |

| ①Safety Controller | 22*5string=110 | Shutdown, monitoring, arc protection |

| ②Smart Transceiver | 5 | PLC transceiver, 485 communication |

| ③Collection box | 5 | Local display, shutdown protection, data upload |

| ④Cloud server | Analyze, manage plant data | |

| ⑤Fonrich PV Management System | Display and manage power station data |